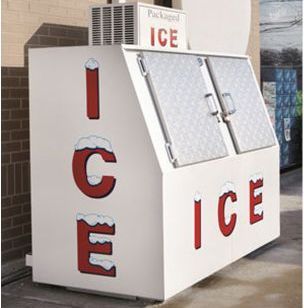

COMMERCIAL

ICE MACHINE REPAIR & SERVICE

Commercial Ice Machine Repair, Cleaning & Maintenance | South Metro Atlanta

Your ice machine is more than a convenience—it's a food service essential. If it fails, your business can suffer lost revenue, bad reviews, or even health code violations.

At John’s Heating, Cooling, and Appliance Repair, we deliver professional commercial ice machine repair, cleaning, and maintenance services to businesses in Peachtree City, Newnan, Sharpsburg, Fayetteville, Griffin, and Metro Atlanta.

We help restaurants, hotels, bars, schools, and medical facilities keep their ice clean, their customers happy, and their systems running year-round.

🔧 Ice Machine Repair Services in

Peachtree City & Atlanta

A broken ice machine can shut down drink service or food safety compliance fast. That’s why we provide fast diagnostics and same-day repairs across Fayette, Coweta, Henry, Spalding, and Fulton Counties.

We repair:

- No or low ice production

- Leaks and blockages

- Ice melting prematurely

- Faulty float switches, valves, and thermostats

- Control board failures

- Electrical and Compressor Issues

🛠️ Brands We Service:

Scotsman, Manitowoc, Hoshizaki, Ice-O-Matic, Kold-Draft, Follett

🧼 Professional Ice Machine

Cleaning Service

Ice is considered a food product under FDA guidelines. Without regular cleaning, mold, bacteria, and biofilm can form inside your machine and contaminate every cube.

Our deep-cleaning process includes:

- Full unit disassembly

- Sanitizing the bin, tubing, evaporator, and water lines

- Removing scale, slime, and mineral deposits

- Replacing filters and cleaning drain pumps

- Testing ice clarity and production rate

🧪 Fun Fact: Mold in your ice bin can form in as little as 3 weeks if humidity is high.

⚙️ Ice Machine Maintenance in Fayette, Coweta, and Metro Atlanta

Avoid costly repairs and service calls with one of our preventive maintenance plans. We check and clean internal parts, calibrate sensors, test water flow and refrigerant pressure, and document all findings.

✅ Improves energy efficiency

✅ Keeps ice sanitary

✅ Helps avoid code violations

✅ Extends unit lifespan

🔄 Perfect for:

- Chain restaurants

- Assisted living facilities

- Event venues

- School cafeterias

- Convenience stores

Service Areas

We serve businesses across:

Cities:

- Peachtree City, GA

- Sharpsburg, GA

- Newnan, GA

- Fayetteville, GA

- Griffin, GA

- Atlanta, GA (Downtown, Midtown, Buckhead, College Park, West End)

Counties:

- Fayette County

- Coweta County

- Henry County

- Spalding County

- Fulton County

📞 Call Now for Expert Ice Machine Service

From emergency repair to routine cleanings and tune-ups, John's Heating, Cooling, and Appliance Repair is your one-stop partner for commercial ice systems. We arrive on time, complete the job correctly, and back our work with integrity.

📲 Call 678-603-7775

How A Ice Machine Turns Water into Ice:

The refrigeration cycle removes heat, causing things to cool. In a commercial ice machine, the cycle removes heat from water and turns it into ice.

Here's how it works:

Compressor: (The compressor is the heart of the system. It causes the freon to move through the sealed system by pumping.) The first step is the compressor. It compresses a hot gas called freon, which increases its temperature and pressure.

Condenser: The high-pressure refrigerant then moves to the condenser, a series of coils cooled by a fan or water. As the refrigerant flows through the coils, it loses heat and returns to a liquid state.

Expansion valve: The liquid refrigerant then passes through an expansion valve, causing a change in pressure and converting the freon into a low-pressure liquid-gas mixture. The freon is now at the saturation point. It becomes vapor as it absorbs heat from the water flowing over the evaporator coil. (Water boiling on a stove is a saturation point. When it absorbs heat, it turns into steam.)

Evaporator: As the low temperature, refrigerant flows into the evaporator. The refrigerant passing through the evaporator absorbs heat from the water, causing it to slowly turn into ice.

Harvest cycle: Once the ice has formed, a harvest cycle begins. The condenser fan turns off, preventing the Freon from releasing the heat it has stored as it passes through the condenser coil. As the freon flows through the evaporator, it heats the coil, causing the ice to melt slightly. The ice then falls off the tubes and into the ice bin.

So, that's how the refrigeration cycle works in a commercial ice machine.

Hoshizaki Manuals - https://www.hoshizakiamerica.com/manuals/

Manitowoc Manuals - https://www.manitowocice.com/Downloads

Ice O Matic Manuals - https://www.iceomatic.com/userfiles/2466/products/prod_61511/B_EC_and_ECP_Series_Tech.pdf

Scottsman Manuals - https://www.scotsman-ice.com/service/Service_Manuals.htm